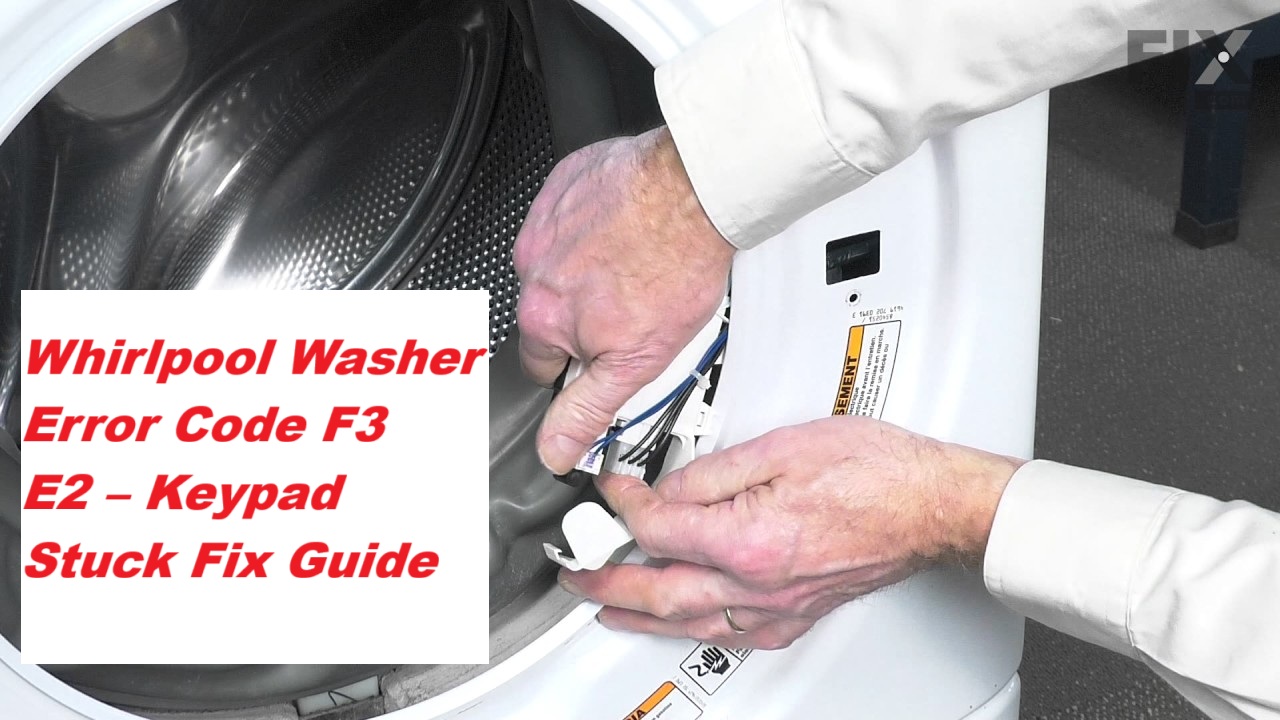

Dealing with the Whirlpool washer error code F3 E2 can be incredibly frustrating, especially when you’re in the middle of a laundry load. This specific error indicates a problem with the keypad or control board, which can be triggered by something as simple as dirt, moisture, or a stuck button.

You’re not alone in facing this issue; it’s quite common and often has straightforward DIY solutions.

One common culprit behind the F3 E2 error is a stuck button on the control panel. If a button gets jammed, it can send a constant signal, causing the error to appear.

To understand more about this error and explore various causes and solutions, I encourage you to read through the entire post. By doing so, you’ll be better equipped to troubleshoot and restore your washer’s functionality without the need for expensive repairs.

What Does the Error Code Mean?

Understanding the F3 E2 error code on your Whirlpool washer is crucial for maintaining its performance. This error typically signals a potential issue with the keypad. Essentially, your washer’s control board is detecting a problem where it believes a button on the keypad may be stuck or faulty.

This situation can arise due to various factors, such as dirt or moisture interfering with the keypad’s operation. When this error code appears, it’s important to address the issue as soon as possible; ignoring it could lead to improper functioning of your washer.

To tackle this problem, start by inspecting the keypad for any visible signs of damage or debris. Gently clean the area around the buttons to ensure they’re free from any contaminants. If the keypad looks clean but the error persists, you may want to perform a reset on your washer. This can often clear minor glitches and restore normal operation.

If these steps do not resolve the issue, it may be a sign of a deeper malfunction, such as a faulty control board or keypad. In that case, consulting a professional technician would be a prudent next step to ensure safe and effective repairs. Remember, addressing these errors promptly not only helps in restoring your appliance’s functionality but also extends its lifespan.

Common Causes of the Error Code

Identifying Potential Causes of the F3 E2 Error Code

Cause 1

If you’ve come across the Whirlpool washer error code F3 E2, it typically points to a problem with the temperature sensor. However, this error can also be triggered by issues with the keypad or buttons that might be stuck. Here are some common causes to consider:

- Debris on the keypad can prevent buttons from responding properly.

- Moisture buildup may lead to electrical shorts, affecting the functionality of the keypad.

- Faulty connections within the control board can disrupt communication between components.

- Worn-out components in the keypad assembly may cause malfunctioning buttons.

- Improper calibration of the temperature sensor can lead to inaccurate readings.

To troubleshoot effectively, start by inspecting the keypad for any debris or moisture that might be causing issues. Make sure all buttons are functioning correctly. If you’ve ruled out these possibilities and the error persists, it may be time to delve deeper into the temperature sensor or the control board for further investigation. Remember, safety is paramount, so always unplug the washer before performing any repairs.

Cause 2

The error code F3 E2 can stem from various underlying issues beyond just the temperature sensor and keypad. One common culprit is a programming error, which can often be resolved with a straightforward programming reset. If your washer’s software has malfunctioned due to a recent update or an interruption during the updating process, this can also trigger the error code. It’s important to check that your washer’s software is current, as outdated software may lead to communication problems between different components.

To perform a programming reset, simply unplug the washer for about a minute and then plug it back in. This allows the machine to reboot, which can clear temporary glitches and help restore normal operation. Taking this step can often prevent further complications and get your washer back to working order. Always remember to prioritize safety when working with electrical appliances, and never hesitate to reach out for professional assistance if you’re unsure.

Cause 3

One of the most common culprits behind the F3 E2 error code in washers is a malfunctioning temperature sensor. This component is crucial because it communicates with the control panel to maintain the appropriate washing temperatures. When the temperature sensor fails, it can disrupt the electrical connection, triggering the error code and affecting your washer’s performance.

Here are some signs that may indicate a faulty temperature sensor:

- Inconsistent Water Temperatures: If you notice that the water temperature fluctuates during wash cycles, it’s a red flag.

- Frequent Error Code Appearances: If the F3 E2 error appears often, the temperature sensor may be at fault.

- Unresponsive Control Panel Settings: Difficulty in adjusting settings could suggest a communication issue stemming from the sensor.

- Visible Wear or Damage: Check for any visible damage on the electrical connections related to the temperature sensor.

- Sudden Temperature Fluctuations: If your washer suddenly changes water temperatures unexpectedly, it’s likely due to a malfunctioning sensor.

Addressing these signs promptly is essential for restoring your washer’s functionality and avoiding further complications. If you suspect that the temperature sensor is the issue, it may be time to consult a professional for a thorough diagnosis and repair. Remember, safety first—always unplug your washer before attempting any repairs or inspections.

Cause 4

While a faulty temperature sensor is indeed a common reason for the F3 E2 error code, it’s important to be aware that other factors can also play a role in this issue. One significant cause could be an electronic malfunction within your washer’s control board. When the control board is compromised, it may exhibit erratic behavior, including sending false signals from the keypad.

Another potential culprit can be related to the keypad itself. Stuck buttons or a damaged ribbon cable can create a loop that constantly triggers the error code. It’s a good idea to inspect the keypad for any debris or signs of damage that might be causing buttons to stick.

If you find that the keypad is the problem, you may need to replace it. Similarly, if you suspect that the control board is at fault, replacing it can often resolve the issue as well. By addressing these electronic malfunctions and keypad problems, you can help restore your washer’s functionality and get it back to working order. Remember, safety comes first—always unplug the appliance before attempting any repairs.

Required Tools to Fix the Error

Essential Tools for Repair

Basic Tools

When addressing the Whirlpool washer error code F3 E2, having the appropriate tools readily available is crucial for a smooth and effective repair. Understanding how to maintain your washer can save you both time and money. Here’s a list of essential tools you’ll need to troubleshoot this issue effectively:

- Screwdrivers: A flathead and a Phillips screwdriver will help you access the control panel and various components of the washer.

- Multimeter: This tool is vital for testing electrical components and diagnosing any electrical issues that may be causing the error code.

- Pliers: Use pliers to handle wires or connectors, especially if you need to make adjustments or secure connections.

- Flashlight: A good flashlight will provide you with better visibility in those hard-to-reach and dimly lit areas of your washer.

- Wire Brush: Cleaning any corrosion from connections with a wire brush can improve electrical contact and performance.

Having these tools at your disposal not only simplifies the troubleshooting process but also enhances your ability to perform the repair safely and effectively. By preparing yourself with the right equipment, you can minimize downtime and resolve the error code quickly, allowing your washer to return to smooth operation. Remember, safety is paramount, so always ensure the washer is unplugged before starting any work.

Supplies

Having the right supplies is crucial for effectively addressing the Whirlpool washer error code F3 E2. First, I recommend gathering a multimeter. This handy tool will allow you to test electrical components and verify their functionality, which is essential for diagnosing the issue accurately. You’ll also need a good set of screwdrivers to disassemble the control panel and access the keypad safely.

To ensure smooth operation, keep a soft cloth or brush nearby. This will help you clean any debris that may have accumulated around the buttons, which could interfere with their performance. It’s also wise to have a replacement keypad on hand. If the current one turns out to be faulty, having a new one will expedite the repair process and minimize downtime.

Pre-Safety Checklist Before Fixing

Before you start any repairs on your Whirlpool washer, it’s crucial to prioritize your safety and ensure the appliance is in good working order. Following the right safety protocols can help you avoid electrical hazards and potential accidents. Here’s a straightforward checklist to ensure you’re prepared:

Prioritizing safety is essential before repairing your Whirlpool washer to avoid electrical hazards and ensure a smooth process.

- Unplug the Washer: Always disconnect the washer from the power source by unplugging it from the outlet. This is the most effective way to prevent electrical shock while you work.

- Check the Surroundings: Make sure the area around the washer is dry and free of any water. A wet environment can increase the risk of electrical shock and create slippery hazards.

- Wear Insulated Gloves: To protect yourself from electrical shock, wear insulated gloves. This is an important safety measure that adds an extra layer of protection while you handle electrical components.

- Inspect for Damage: Take a moment to visually inspect the power cord and any other visible components for signs of damage, such as fraying or exposed wires. If you notice any issues, it’s best to address them before proceeding.

- Organize Your Tools: Keep your tools neatly organized and away from any water sources. A clutter-free workspace will help you work more efficiently and safely.

Diagnose the Error Code

Now that you’ve ensured a safe working environment, let’s dive into diagnosing the F3 E2 error code on your Whirlpool washer. First and foremost, unplug the unit to prioritize your safety before you begin any troubleshooting.

Next, take a close look at the keypad. Stuck buttons can often trigger this error code, so gently press each button to ensure they’re functioning properly. If you notice any buttons that are unresponsive or stuck, that could be your culprit.

Consult your user manual for specific diagnostic procedures. This will guide you through checking for any irregular readings that might be contributing to the error. If you have a multimeter handy, it can be a useful tool to test the continuity of the connections on the control board.

Interpreting error codes is crucial; a persistent F3 E2 typically suggests there’s a malfunction either in the keypad or the control board itself. Keep detailed notes of any findings, as this information can be invaluable for further troubleshooting or when you reach out for professional assistance. Remember, patience and a methodical approach are key to resolving these issues effectively.

Step-by-Step DIY Troubleshooting Guide

Transitioning to Targeted Troubleshooting Steps

Fix for Cause 1

When you encounter the F3 E2 error code on your Whirlpool washer, it’s essential to address the issue promptly to avoid further complications. This error typically points to problems related to the keypad. Here’s a step-by-step guide to effectively troubleshoot the keypad:

- Unplug the washer: Start by disconnecting the washer from the power source. Leave it unplugged for at least 10 minutes. This will allow the system to reset, which can sometimes clear minor error codes.

- Inspect the keypad: Carefully examine the keypad for any visible signs of damage, such as cracks or broken buttons. Also, check for dirt, lint, or debris that may be obstructing the buttons from functioning properly.

- Reattach connections: If you’re comfortable doing so, open the control panel of the washer. Look for any loose or disconnected wiring. Ensure that all connections are secure and properly attached, as a loose wire can lead to keypad malfunctions.

- Run a diagnostic test: Once you’ve checked the connections, plug the washer back in. Many Whirlpool washers have a built-in diagnostic mode. Refer to your user manual for specific instructions on how to initiate this mode. Running a diagnostic test can help identify if the issue is still present.

- Observe error code interpretation: If the F3 E2 error code reappears after running the diagnostic, further investigation may be necessary. It could indicate that the keypad itself needs to be replaced or that there is a deeper issue within the control board.

Fix for Cause 2

If you’ve ruled out keypad issues as the cause of the F3 E2 error code, it’s time to turn your attention to the temperature sensor. First and foremost, ensure your safety by disconnecting the washer from the power source.

Next, locate the temperature sensor, which is usually situated near the inlet valve or inside the drum. Inspect the wiring for any signs of damage or loose connections, as these can lead to incorrect readings and trigger the error code.

To check the sensor’s functionality, use a multimeter to measure its resistance. It’s important to compare your readings against the manufacturer’s specifications to confirm whether it’s operating as it should. If your readings fall outside the acceptable range, replacing the sensor is the best course of action.

After you’ve made any necessary repairs or replacements, reconnect the power and run a test cycle to see if the issue has been resolved. By following these detailed troubleshooting steps, you can effectively address the F3 E2 error code and get your washer back in proper working order. If you have any further questions or need additional assistance, don’t hesitate to reach out.

Fix for Cause 3

As you continue troubleshooting the F3 E2 error code, the next crucial step is to examine the control board, as it can frequently be the root cause of the issue. Understanding how to interpret error codes accurately is essential for effective troubleshooting. Here’s a straightforward guide to help you navigate this process safely and effectively:

- Power off the washer and unplug it from the outlet to ensure your safety before proceeding.

- Inspect the control board carefully. Look for any signs of burnt components, such as discoloration or melted areas, and check for loose connections that may affect performance.

- Examine the wiring harness connected to the control board. Look for signs of damage, wear, or corrosion, as these can lead to connectivity issues.

- Test the control board with a multimeter. This tool will help you check for continuity and voltage, which are crucial for ensuring the board is functioning correctly.

- Reassemble the washer and plug it back in. Power it on to see if the F3 E2 error code still appears. If the error persists, further investigation may be necessary.

Fix for Cause 4

To effectively address the F3 E2 error code, it’s essential to focus on the pressure switch, which is crucial for monitoring water levels in your washer. Safety is our top priority, so start by unplugging your washer to prevent any electrical hazards.

Next, locate the pressure switch, usually situated near the water inlet. Take a moment to inspect the switch for any visible signs of damage or debris that could be affecting its performance. Carefully disconnect the pressure switch harness, and using a multimeter, check for continuity. If your multimeter indicates no continuity, it’s time to replace the pressure switch.

Don’t forget to examine the hose connected to the pressure switch as well. Kinks or blockages in this hose can lead to false error code readings, which might mislead you in your troubleshooting efforts.

After addressing any issues you find, reconnect everything securely. Once you’ve plugged the washer back in, run a cycle to confirm that the F3 E2 error code has been resolved. Empowering yourself with this knowledge can save you time and money, and help you maintain the longevity of your appliance.

Call a Professional If

While troubleshooting the Whirlpool washer error code F3 E2 can often be managed at home, it’s important to know when to call a professional for help. If the problem continues after you’ve performed the basic checks, seeking expert assistance is a wise choice to prevent further damage. Here are some signs that indicate you should reach out to a qualified technician:

- The error code keeps reappearing even after you’ve reset the machine.

- The keypad is unresponsive despite your troubleshooting efforts.

- You’re hearing unusual noises during the wash cycle that weren’t present before.

- You notice any signs of physical damage to the washer, like cracks or leaks.

- Attempting unauthorized repairs could void your warranty.

A skilled technician can accurately diagnose the issue and ensure your washer operates safely and efficiently. This not only protects your investment but also gives you peace of mind knowing that the repair is handled correctly. Remember, it’s always better to seek professional help for long-term efficiency and safety. Don’t hesitate to reach out for expert assistance when needed.